Parameters and indicators:

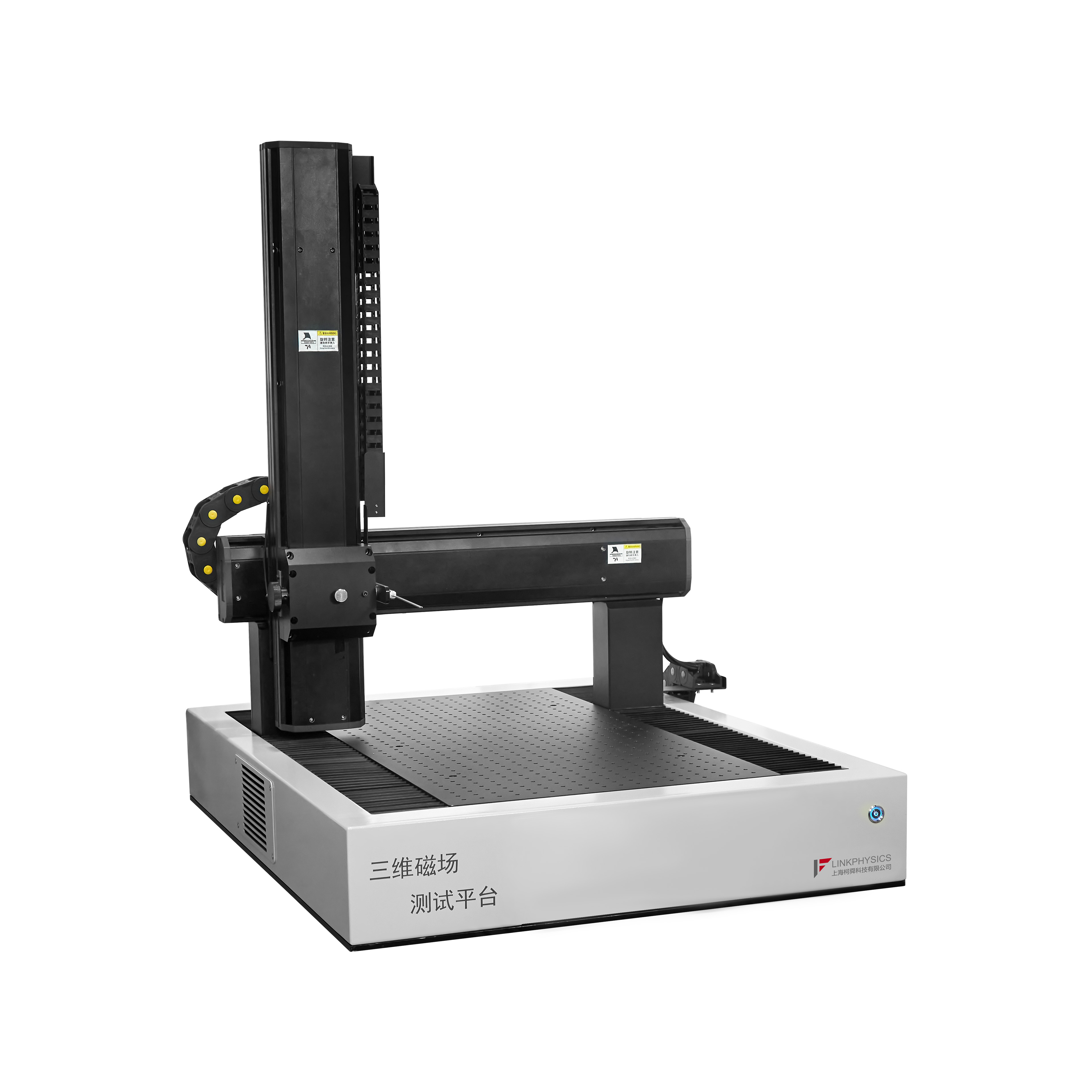

Three-dimensional magnetic field test platform base

The base of the three-dimensional magnetic field testing platform includes a sample placement platform, a base cavity, and vibration damping feet. The sample placement platform measures 90cm*48cm (350mm travel model) and is used for placing magnetic samples. The base cavity is hollow and is equipped with a motion controller for the three-dimensional motion system inside. There are four vibration damping feet made of rubber, which have a vibration damping effect. The height of the four feet of the platform base can be adjusted through the bolts in the feet.

| Weight | 250 Kg

|

Overall dimensions

| It measures 80cm in length, 105cm in width and 112cm in height

|

Sample area dimensions

| 90cm*48cm

|

Vibration reduction method

| Rubber foot pads |

Three-dimensional motion system

The three-dimensional motion system includes X, Y, and Z three-axis motors and motion controllers. The motion controller controls the movement of the X, Y, and Z three-axis motors through software, thereby driving the movement of the gaussmeter probe to test the magnetic field strength in space.

X-axis movement stroke

| 350 mm

|

Y-axis movement stroke

| 350 mm

|

Z-axis movement stroke

| 350 mm

|

Moving speed

| Adjustable,50mm/s

|

Movement accuracy

| Adjustable

|

Control mode

| Software

|

Adjustable displacement accuracy

| 0.01 mm

|

| X-axis movement stroke | 200 mm

|

Y-axis movement stroke

| 200 mm

|

| Z-axis movement stroke | 200 mm

|

Moving speed

| Adjustable,50mm/s

|

Movement accuracy

| Adjustable

|

Control mode

| Software

|

Adjustable displacement accuracy

| 0.01 mm

|

Software control system:

The control software is installed on the all-in-one computer and connected to the 3D motion controller and gaussmeter via a data cable to achieve communication. It can control the movement of the 3D motion system and record the magnetic field intensity data. It can realize functions such as one-click start and stop, manual scanning, 3D automatic scanning, data analysis, and generation of gradient graphs. One-click start and stop: The one-click start and stop of motion can achieve functions such as one-click control to the three-dimensional target coordinate and one-click zeroing.