- Home

- About

-

Products

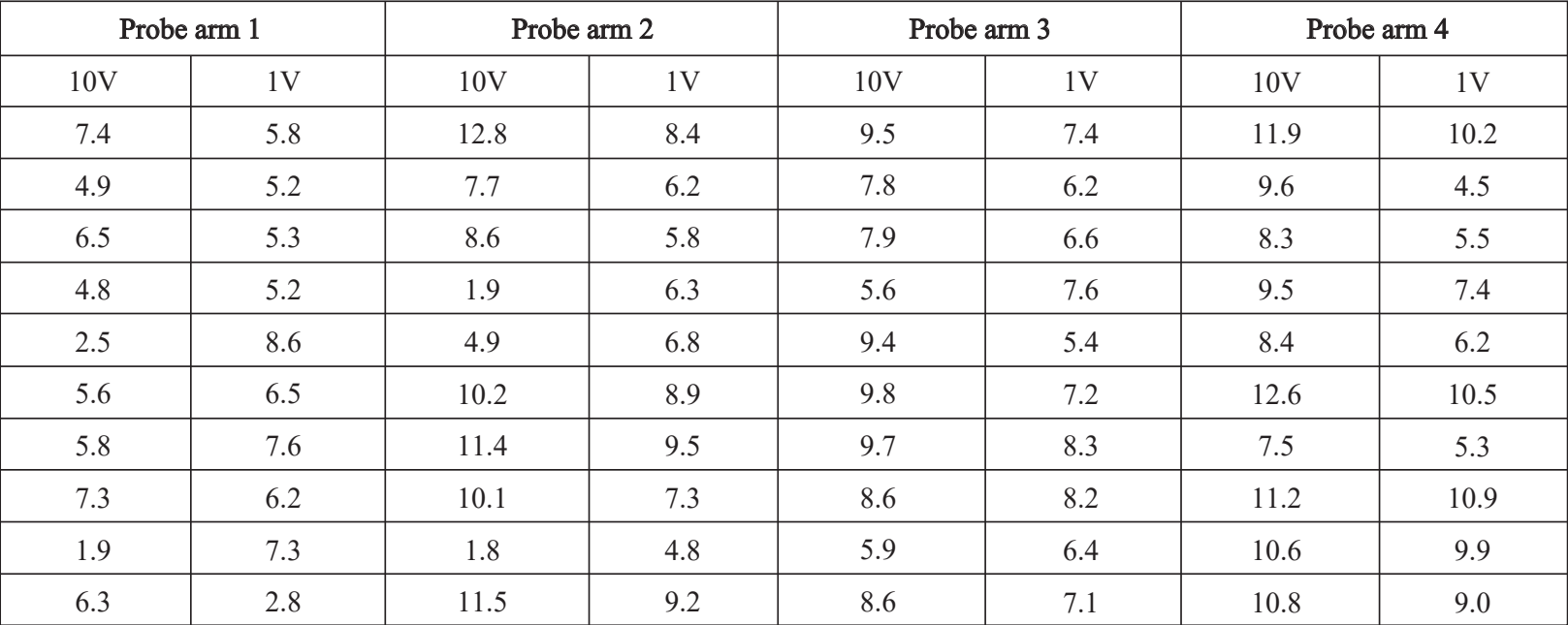

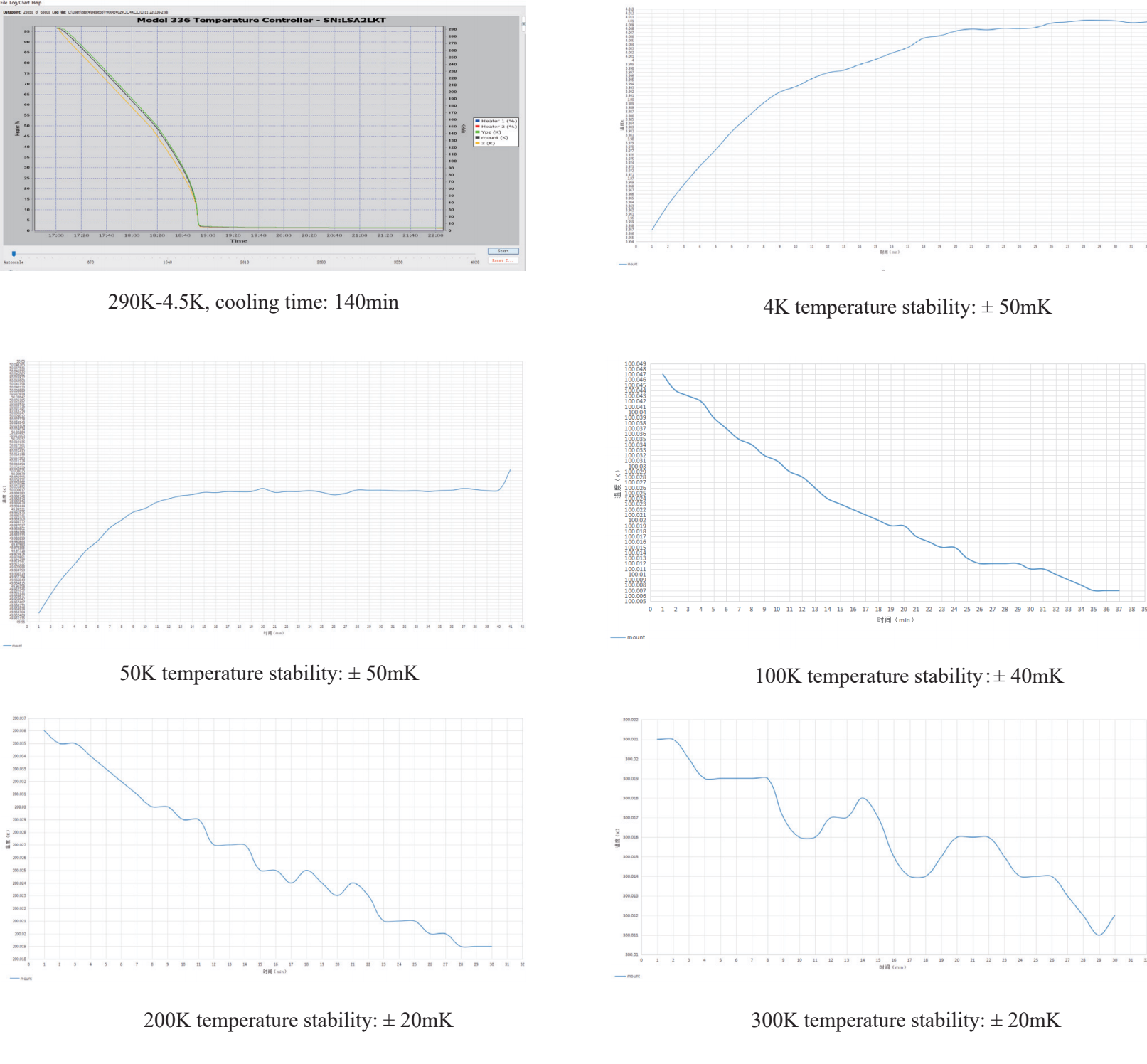

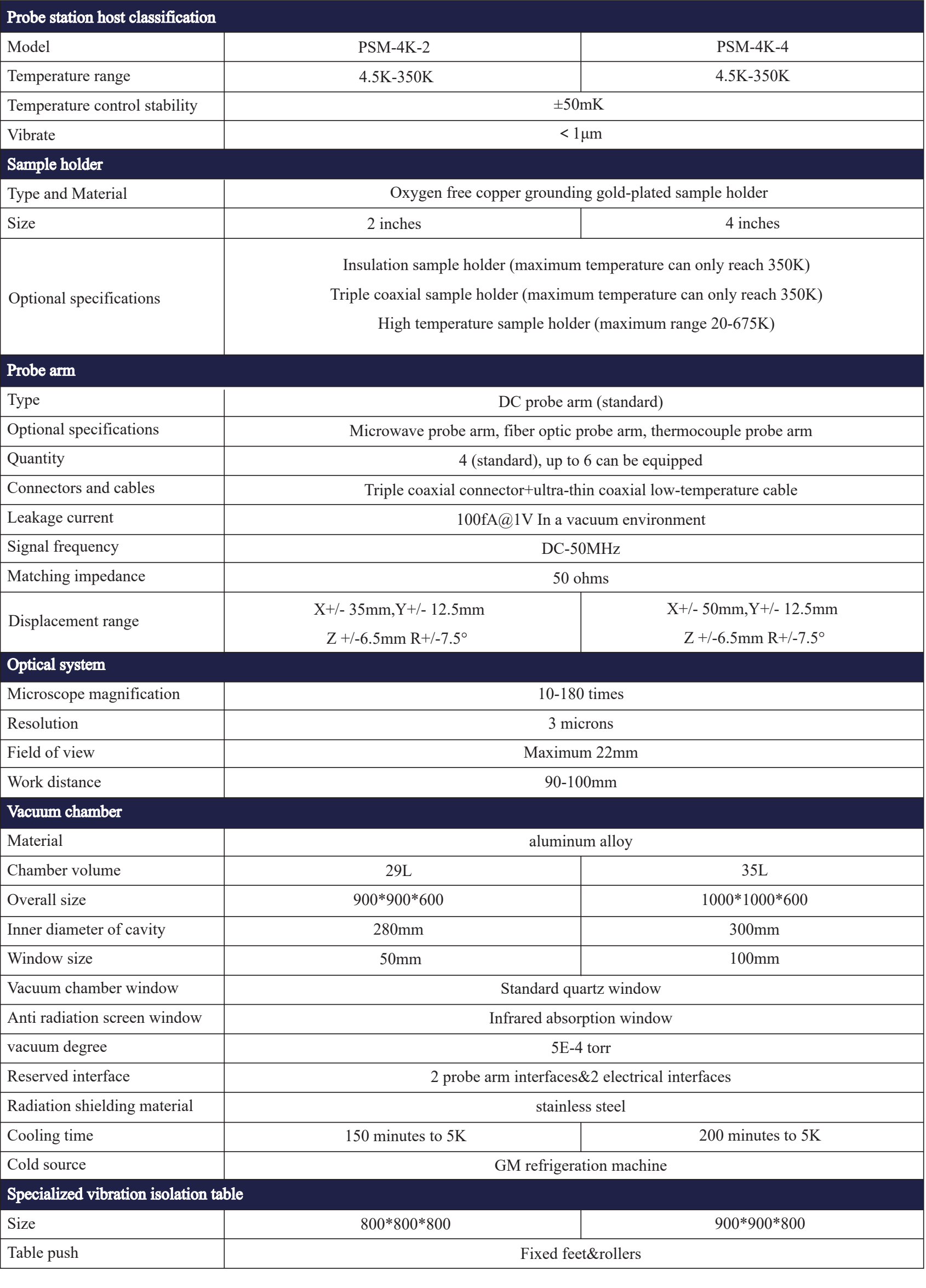

- Probe Stations

- Superconducting Magnet Systems

- Cryostat

- Hall Effect Test System

- Three-dimensional magnetic field test rig

- Temperature sensor

- Temperature Controllers & Monitors

- Low-temperature sample rod

- Delft Circuits

- Agilent Molecular Pumps

- Cryogenic Accessories

- Cryocoolers

- Junction box

- Permanent magnet

- Probe Stations

- News

- Customer

- Support

- Contact us